Polypropylene (PP) is a thermoplastic polymer produced through the polymerization of propylene monomers, resulting in a semi-crystalline structure that provides mechanical strength and chemical stability. The material serves a wide range of industries, with polypropylene uses spanning automotive components, packaging materials, consumer products, and textile fibers. Its lightweight nature reduces transportation costs and supports ergonomic design, while its durability protects against wear and mechanical stress. Polypropylene plastic resists chemical degradation, allowing for safe contact with reactive substances and supporting long-term performance in both industrial and household settings. Recyclable polypropylene contributes to sustainable manufacturing by enabling reprocessing and reuse, thereby reducing waste and supporting circular production systems. The widespread adoption of PP reflects its balance of performance, cost-efficiency, and environmental responsibility.

What is Polypropylene (PP)?

Polypropylene (PP) is a thermoplastic polymer widely used in packaging, automotive components, and consumer products due to its balance of mechanical strength and lightweight structure. The PP material supports everyday applications by offering durability without adding excess weight, which contributes to efficient production and transport. Its chemical resistance protects against degradation from acids, bases, and solvents, making it suitable for use in harsh environments. The recyclability of polypropylene supports sustainable manufacturing practices by allowing reprocessing and reuse across various industries. The answer to the question “What is polypropylene?” reflects a material designed for versatility, reliability, and environmental responsibility.

How is Polypropylene Made?

Polypropylene is produced through a controlled polymerization process that transforms propylene gas into a versatile thermoplastic. The method begins with the polymerization of propylene gas using Ziegler-Natta or metallocene catalysts, which initiate the formation of long molecular chains. The reaction creates a semi-crystalline structure that supports mechanical strength and chemical resistance. The resulting polypropylene polymerization yields a material that is shaped into films, fibers, and molded components through processes such as extrusion, injection molding, or blow molding. The flexibility of the polypropylene process enables manufacturers to tailor polypropylene for various applications, including packaging, automotive parts, textiles, and consumer goods. The answer to the question “How is polypropylene made?” reflects a scalable and efficient production method that supports high-volume applications across multiple industries.

What is the Full Form of PP?

The full form of Polypropylene (PP) is polypropene, the systematic or chemical name. PP plastic supports a wide range of industrial applications due to its lightweight structure and efficient processing behavior. The material is widely used in packaging, automotive parts, and consumer goods, where durability and affordability are essential. The full form of PP reflects a material that meets performance demands across sectors requiring cost-effective and reliable plastic solutions.

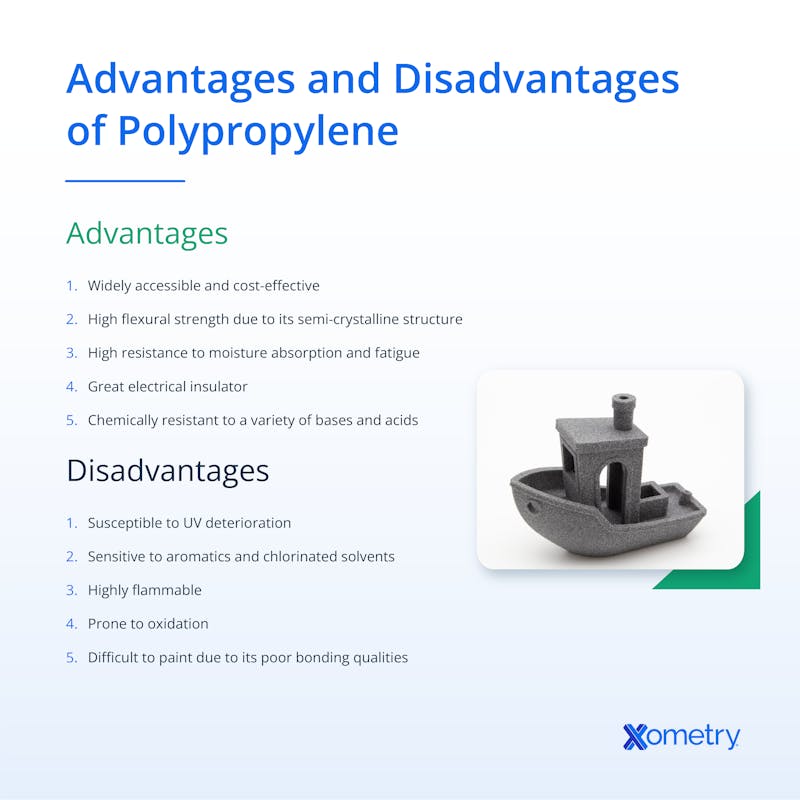

What are the Advantages of Polypropylene?

The Advantages of Polypropylene are listed below.

- Polypropylene is produced at a relatively low cost, which supports high-volume manufacturing without compromising material quality. The economic benefits make it suitable for both disposable goods and durable components.

- The polymer is reprocessed and reused, which supports sustainability efforts in industrial and consumer sectors. Its recyclability reduces waste and promotes circular production models.

- Polypropylene maintains stability at processing temperatures between 160°C and 170°C, which supports molding and extrusion operations. The thermal behavior allows its use in applications requiring moderate heat exposure without deformation.

What are the Disadvantages of Polypropylene?

The Disadvantages of Polypropylene are listed below.

- Prolonged exposure to ultraviolet light weakens polypropylene’s molecular structure, leading to brittleness and discoloration. The polypropylene issues restrict its use in outdoor applications without the addition of stabilizing additives.

- Polypropylene is highly flammable and supports combustion once ignited. The characteristic limits its suitability in environments where fire resistance is a critical requirement.

- Polypropylene lacks the mechanical robustness needed for high-load or structural components, while it offers good strength for general applications. The limitation reduces its effectiveness in industrial or high-stress settings where stronger materials are necessary.

What are the Properties of Polypropylene?

The properties of Polypropylene are listed below.

- Polypropylene has a density of 0.895-0.92 g/cm³, which reduces the overall material weight. The property supports lightweight designs in containers, vehicle parts, and fiber-based goods.

- Polypropylene resists mechanical stress without fracturing, thereby maintaining product integrity during use and transportation. Its strength supports structural applications that require durability.

- The polymer absorbs force without cracking, which protects molded items from damage during handling. The resilience supports packaging and automotive parts that are repeatedly contacted.

- Polypropylene material properties withstand processing temperatures between 160°C and 170°C without degrading. The thermal range supports injection molding and heat-based fabrication methods used across industrial sectors.

What is the Density of Polypropylene?

The density of polypropylene ranges from 0.895 g/cm³ to 0.92 g/cm³, making it one of the lightest thermoplastics used in manufacturing. The low density of PP supports weight reduction in automotive parts, packaging materials, and consumer goods without compromising structural integrity. The density of polypropylene contributes to efficient transport and handling, which reduces energy consumption during production and distribution. The material’s lightweight nature, combined with its durability and chemical resistance, makes it a preferred choice for applications requiring strength and reduced mass.

What is the Melting Point of Polypropylene?

The melting point of polypropylene (PP) ranges from 160°C to 170°C, placing it among thermoplastics suitable for moderate heat applications. The temperature range allows the material to maintain its form and function under elevated processing conditions. The PP melting point supports injection molding operations that require consistent flow and solidification for producing detailed components. The melting point of polypropylene contributes to its use in packaging, automotive parts, and consumer products that demand thermal stability without compromising mechanical strength. The material’s ability to withstand high molding temperatures while retaining durability makes it a preferred choice for manufacturers seeking reliable performance in heat-formed products.

What is the Chemical Formula of Polypropylene?

The chemical formula of polypropylene is represented as “(C₃H₆)ₙ,” where “n” indicates the number of repeating propylene monomer units in the polymer chain. The structure forms a hydrocarbon backbone with methyl groups that influence the material’s physical behavior. The chemical formula of polypropylene supports flexibility by allowing controlled movement between chains without compromising cohesion. The polypropylene chemical formula contributes to its resistance to acids, bases, and solvents, protecting the material in chemically active environments. Strength and moldability arise from the balanced arrangement of carbon and hydrogen atoms, making it suitable for applications requiring durable, formable thermoplastics. The composition supports its widespread use in packaging, the automotive industry, and consumer products.

What is the Structure of Polypropylene?

The structure of polypropylene consists of propylene monomers connected by carbon-carbon bonds, forming either a linear or branched molecular structure. Each repeating unit has a methyl group (-CH₃) attached to every other carbon atom, which creates steric hindrance and adds to the polymer’s stiffness. The methyl substitution influences the crystallinity of the polypropylene structure, enabling the material to form semi-crystalline regions that enhance mechanical strength and impact resistance. The structure of polypropylene plays a crucial role in its performance across various applications, including packaging, automotive, and industrial sectors, which require durability and dimensional stability.

What is Polypropylene Used for?

Polypropylene is used for packaging, automotive, textile, and consumer product industries due to its adaptable properties and efficient processing. The material enables the large-scale manufacturing of items that require moisture resistance, mechanical durability, and lightness. Polypropylene is used in various applications, including bottles, food containers, and furniture, where its durability and chemical stability contribute to long-term performance. The answer to what polypropylene is used for reflects its role in applications that demand cost-effective materials with consistent quality and reliable structural integrity. Polypropylene remains a preferred choice for manufacturers seeking versatility across functional and aesthetic product categories.

What is Polypropylene Used for in Medical Applications?

Polypropylene is used for medical applications due to its biocompatibility, chemical resistance, and ability to withstand sterilization processes. Polypropylene medical applications (syringes, catheters, surgical sutures, diagnostic devices, and pill containers), where safety and durability are essential. The material resists bacterial contamination and maintains structural integrity during steam sterilization, which supports hygienic performance in clinical environments. Its inert chemical nature prevents reactions with bodily fluids and pharmaceutical compounds, contributing to the safe and reliable use of direct-contact medical products. Polypropylene for medical use meets the functional and regulatory demands of disposable and reusable healthcare items, offering a balance of cost efficiency and patient safety.

Can Polypropylene be Used in Medical Implants?

Yes, Polypropylene can be used in certain medical implants that require biocompatibility and mechanical performance. The material supports applications such as hernia mesh and joint replacements due to its ability to maintain structural integrity while remaining inert in biological environments. The answer to the question “What is polypropylene?” includes its role in implantable devices that demand flexibility without compromising strength. Polypropylene resists chemical degradation and does not provoke adverse tissue reactions, which contributes to its acceptance in surgical procedures. Its molecular structure allows controlled deformation and long-term durability, which supports safe integration within the human body. Polypropylene meets the functional and safety requirements for select implantable products where cost efficiency and material stability are essential.

What are the Applications of Polypropylene in Construction?

The applications of Polypropylene in construction are listed below.

- Roofing Membranes: Polypropylene offers waterproofing that resists environmental exposure and maintains flexibility across a wide range of temperatures.

- Insulation Materials: The material provides thermal resistance, supporting energy-efficient building envelopes and reducing heat transfer.

- Pipes and Fittings: Polypropylene resists corrosion and chemical degradation, which supports long-term performance in plumbing systems.

- Protective Sheets and Barriers: Its lightweight structure and chemical inertness allow use in vapor barriers and protective linings.

- Concrete Form Liners: The material supports reusable mold surfaces that maintain dimensional accuracy and resist sticking.

What Role Does Polypropylene Play in Automotive Safety Features?

The role that Polypropylene plays in automotive safety features is listed below.

- Airbag Systems: Polypropylene supports inflation mechanisms by providing lightweight housings that resist deformation and maintain shape during deployment.

- Bumpers: The material absorbs impact forces and distributes energy across its surface, reducing damage during collisions and protecting underlying structures.

- Dashboards: Polypropylene maintains dimensional stability and resists cracking under stress, which supports consistent performance in crash scenarios.

- Door Panels: The material provides a balance of rigidity and flexibility, which helps absorb side-impact forces and maintain passenger protection.

- Interior Trims: Polypropylene provides durable finishes and maintains shape under thermal and mechanical stress, contributing to long-term safety and comfort.

What are the Benefits of Polypropylene in Food Packaging?

The benefits of Polypropylene in food packaging are listed below.

- Non-toxic Composition: The material meets food safety standards and resists chemical interaction with stored contents.

- Durability: Polypropylene maintains structural integrity during handling, transport, and storage without cracking or deforming.

- Moisture Resistance: The polymer prevents water absorption and protects contents from humidity and external contamination.

- Cost-Effectiveness: Low production costs and efficient processing support large-scale packaging with minimal material waste.

- Thermal Stability: The material tolerates temperature variations during filling, sealing, and storage without compromising performance.

What are the Main Challenges in Manufacturing Polypropylene?

The main challenges in manufacturing Polypropylene are listed below:

- Melting Temperature Sensitivity: Polypropylene requires precise thermal control during molding due to its narrow processing window, which increases the risk of warping or incomplete fills.

- Product Consistency: Variations in cooling rates and mold design can influence dimensional accuracy and surface finish, complicating quality control across production batches.

- Low Recycling Rates: The material’s widespread use in mixed plastic applications and limited sorting infrastructure reduce its recovery and reuse, contributing to environmental strain.

How does Polypropylene Affect the Quality of Products?

Polypropylene affects the quality of products by offering a balance of tensile strength, impact resistance, and flexibility, ensuring reliable performance across various applications. Polypropylene withstands mechanical stress without fracturing, enhancing durability in products subjected to repeated use or movement. Its flexibility allows it to deform without permanent damage, maintaining structural integrity under moderate loads. Its moderate flexibility makes it ideal for products that do not require extreme flexibility, while polypropylene is relatively rigid compared to other flexible materials. Polypropylene supports precise molding into complex shapes, ensuring consistent dimensions and smooth finishes across production batches. The ability to form detailed geometries without compromising strength results in robust and well-formed products. These characteristics make polypropylene a dependable and cost-effective material for manufacturers seeking both functional and aesthetic quality in their products. However, polypropylene is not the best choice for applications requiring high aesthetic precision or high-gloss finishes compared to materials like polystyrene or polycarbonate.

What is the Cost of Polypropylene Compared to Other Plastics?

The cost of Polypropylene (PP) is generally lower than that of other plastics, such as polycarbonate, Acrylonitrile Butadiene Styrene (ABS), and Polyethylene Terephthalate (PET), due to its minimal processing requirements and abundant raw material availability. Polypropylene’s production process involves less energy consumption and simpler molding conditions, making it more cost-effective for mass production. Polycarbonate demands higher thermal stability and precision tooling, which increases its production costs. ABS offers improved impact resistance but requires greater material costs and more complex processing. PET, while ideal for applications requiring clarity and strength, is more expensive due to its complex polymer structure and higher melting point. Polypropylene is a cost-effective choice for large-scale operations prioritizing affordability, chemical resistance, and flexibility over higher-performance mechanical properties.

Is Polypropylene (PP) more Cost-Effective than Polycarbonate (PC)?

Yes, Polypropylene (PP) is more cost-effective than Polycarbonate (PC) when high strength is not a primary requirement. Polypropylene requires less energy to process and uses lower-cost raw materials, reducing production expenses across both large and small manufacturing volumes. The material supports applications that prioritize affordability and flexibility over impact resistance or thermal stability. Polycarbonate offers superior mechanical strength and optical clarity, but its higher processing temperature and specialized tooling increase operational costs. Polypropylene suits products that demand chemical resistance, lightweight construction, and economic value without the need for high structural performance. The cost difference reflects the distinct roles each material plays in design and manufacturing, with Polypropylene favored for budget-sensitive applications and Polycarbonate reserved for parts requiring durability and precision.

Does Polypropylene (PP) Have Better Impact Resistance Than High-Density Polyethylene (HDPE)?

No, Polypropylene (PP) does not have better impact resistance than High-Density Polyethylene (HDPE). HDPE offers superior flexibility and better impact absorption, making it ideal for applications that require durability under stress or deformation. Polypropylene, while providing moderate toughness, exhibits higher rigidity and is more prone to cracking under repeated impacts. The molecular structure of HDPE allows for better energy dispersion during collisions, whereas Polypropylene favors rigidity and shape retention. High-Density Polyethylene (HDPE) is preferred in environments where impact resistance and flexibility are crucial, while Polypropylene is favored for applications that emphasize chemical resistance and dimensional stability.

Is Polypropylene (PP) More Flexible Than Acrylonitrile Butadiene Styrene (ABS)?

Yes, Polypropylene (PP) is more flexible than Acrylonitrile Butadiene Styrene (ABS) due to its higher elongation at break and lower stiffness. The molecular structure of Polypropylene allows greater deformation under stress without fracturing, which supports applications requiring bendability and fatigue resistance. ABS maintains higher rigidity and impact strength, but limits flexibility in dynamic environments. Polypropylene offers a balance of chemical resistance and ductility, making it suitable for parts that require repeated movement or stress absorption. In contrast, Acrylonitrile Butadiene Styrene (ABS) favors structural stability and dimensional control.

Does Polypropylene (PP) Offer Better Chemical Resistance Than High Impact Polystyrene (HIPS)?

Yes, Polypropylene (PP) offers better chemical resistance than High Impact Polystyrene (HIPS) due to its non-polar molecular structure and higher tolerance to corrosive substances. PP resists degradation when exposed to acids, bases, and a wide range of organic solvents, making it suitable for environments requiring long-term chemical stability. HIPS provides moderate resistance but remains vulnerable to certain solvents and oxidizing agents, which limits its performance in chemically aggressive environments. PP is preferred for applications where exposure to reactive compounds is expected, while High Impact Polystyrene (HIPS) suits roles that prioritize impact strength and surface finish over chemical durability.

Is Polypropylene (PP) More Commonly Used Than Polylactic Acid (PLA)?

Yes, Polypropylene (PP) is more commonly used than Polylactic Acid (PLA) in industrial applications due to its lower cost, wider chemical resistance, and greater processing flexibility. Polypropylene meets a variety of manufacturing needs, including packaging, automotive components, and consumer goods, where durability and chemical stability are crucial. Its resistance to acids, bases, and moisture ensures reliable performance in environments exposed to reactive substances. Polylactic Acid is derived from renewable sources and is used in applications that prioritize biodegradability and environmental impact (food packaging and 3D printing). Polylactic Acid (PLA) exhibits lower thermal resistance and mechanical strength, limiting its use in high-stress or high-temperature environments. Polypropylene remains a preferred material for large-scale manufacturing due to its excellent balance of mechanical properties, affordability, and compatibility with various molding processes.

Does Polypropylene (PP) Have a Higher Melting Point Than Polyethylene Terephthalate (PET)?

No, Polypropylene (PP) does not have a higher melting point than Polyethylene Terephthalate (PET). Polypropylene melts at a lower temperature than PET, which limits its effectiveness in high-temperature environments. Polypropylene typically melts at around 160°C to 170°C, while PET has a melting point around 250°C to 260°C, due to its more crystalline structure. PET remains thermally stable at high temperatures because of its crystalline structure and higher melting point, making it ideal for applications involving heat exposure or sterilization. It loses mechanical strength when exposed to sustained heat beyond its thermal threshold, while polypropylene offers cost-effective production and chemical resistance. Polyethylene Terephthalate (PET) is preferred for packaging and industrial parts that require withstanding thermal stress, whereas Polypropylene is favored for projects emphasizing flexibility, moisture resistance, and cost-effectiveness.

Is Polypropylene (PP) More Suitable for Food Packaging Than Nylon (PA)?

Yes, Polypropylene (PP) is more suitable for food packaging than Nylon (PA) due to its combination of low cost, moisture resistance, and biocompatibility. The material resists water absorption and maintains chemical stability when exposed to food substances, which supports hygienic storage and extended shelf life. Nylon (PA) offers higher mechanical strength and abrasion resistance; however, its tendency to absorb moisture and its higher production cost limit its effectiveness in food-related applications. Polypropylene meets safety standards for direct food contact and supports efficient processing in high-volume packaging environments. Its balance of affordability, durability, and inertness makes it a preferred choice for food containers, wraps, and storage solutions.

Does Polypropylene (PP) Perform Better Than Polybutylene Terephthalate (PBT) in High-Temperature Applications?

No, Polypropylene (PP) does not perform better than Polybutylene Terephthalate (PBT) as it is not suitable for high-temperature applications due to its lower thermal resistance and reduced dimensional stability under heat. PBT maintains its structural integrity at high temperatures and resists deformation during prolonged exposure, making it suitable for use in electrical, automotive, and industrial applications. Polypropylene softens at lower temperatures and loses mechanical strength under thermal stress, limiting its effectiveness in high-heat environments. Polybutylene Terephthalate (PBT) offers greater thermal stability and durability, while Polypropylene remains suitable for applications where moderate temperature demands and cost efficiency are prioritized.

Is Polypropylene (PP) Stronger Than Acetal (POM) in Terms of Stiffness?

No, Polypropylene (PP) is less intense than Acetal (POM) due to its higher modulus and increased resistance to deformation under load. Acetal offers superior dimensional stability and mechanical rigidity, making it well-suited for precision parts and structural uses. Polypropylene offers flexibility and chemical resistance, but lacks the stiffness necessary for parts that require tight tolerances and consistent shape retention. Acetal (POM) delivers superior performance in environments requiring high mechanical strength and minimal deflection, whereas Polypropylene is suitable for applications that emphasize ductility and cost savings.

Summary

Due to its flexibility, durability, chemical resistance, and other important properties, polypropylene has found its applications in many different industries, with the packaging industry being its number one user. This BPA-free thermoplastic polymer is not considered to be hazardous to human health, but it might deteriorate or even leach chemicals when extensively exposed to UV rays or extremely high temperatures. There exist several different molding processes for plastics manufacturing, but polypropylene is primarily processed with the injection molding technique.

Need polypropylene injection molding for your parts? Xometry's experts can help! Get a quote on your designs today!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry's network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.