Polyamide (PA) belongs to a family of synthetic polymers typically formed through the reaction of diamines and dicarboxylic acids, or by ring-opening polymerization of lactams. Nylon is an aliphatic Polyamide that is made for strength, durability, and flexibility. PA plastic possesses excellent mechanical strength and versatility, which makes it applicable to textiles, automotive parts, and industrial machinery. Polyamide (nylon) has a structure featuring repeating amide bonds, which give it high tensile strength and durability. The properties make it suitable for long-lasting applications such as gears, fasteners, and fabrics.

Nylon combines toughness and flexibility, performing well under mechanical stress. Nylon resists abrasion and impact, making it suitable for moving parts and friction-exposed surfaces. Polyamide remains stable at high temperatures, vital for heated components. PA plastic resists many oils and fuels but can be attacked by strong acids and some polar solvents, so chemical compatibility must be verified for each application.

Polyamide can be mechanically recycled, but repeated processing reduces molecular weight and strength, so recyclability is limited compared to some thermoplastics. Its reusability reduces waste and aids circular production. Polyamide offers reliable strength, thermal resistance, and environmental adaptability in electronics, construction, and consumer goods. Its mechanical, thermal, and chemical properties make PA a dependable choice for demanding applications.

What Is Polyamide?

Polyamide refers to a category of polymers created through the chemical bonding of amide groups (diamines and dicarboxylic acids). The molecular structure of polyamide material contributes to its strength and resistance to mechanical stress. PA plastic (nylon) has gained recognition for its performance in textiles, engineering plastics, and industrial components. The PA material supports long-term use due to its toughness and ability to maintain shape under pressure. In textile production, polyamide fibers provide durability and flexibility, which contribute to the longevity of garments and technical fabrics. PA plastic serves as a reliable choice for engineering applications that require dimensional stability and wear resistance. Industrial applications benefit from polyamide’s ability to withstand repeated mechanical loads and exposure to environmental conditions. The combination of structural integrity and resilience has positioned polyamide as a dependable material across sectors that demand consistent performance.

How Is Nylon Material Made?

Nylon material is made by a condensation polymerization process involving hexamethylenediamine and adipic acid. The reaction forms long chains of repeating amide bonds, releasing water as a byproduct and creating a stable polymer structure. The resulting nylon plastic exhibits high strength and thermal resistance, which supports its use in demanding mechanical and industrial environments. The polyamide material is cooled, pelletized, and either spun into fibers or molded into components after polymerization, based on the intended application. The common variant is Polyamide 6, which is synthesized from caprolactam and processed similarly to produce textiles, automotive parts, and consumer goods. The versatility of nylon fiber stems from its molecular structure, which allows for constant performance across various manufacturing formats.

What Is the Nylon Full Form?

The term ‘nylon’ refers to a family of synthetic polyamides (PA) rather than an abbreviation or acronym. Nylon is a class of synthetic polymers containing repeating units linked by amide bonds. The first successful synthesis of nylon 6,6 was achieved in 1935 during research by Wallace Carothers and his team at DuPont. The development marked a major milestone in polymer science, introducing a material with high strength, flexibility, and resistance to abrasion. Nylon gained widespread use because of its ability to perform reliably across various mechanical and environmental conditions. Nylon offers durability, elasticity, and wear resistance for garments, upholstery, and industrial uses. PA supports structural functions with toughness, stability, and thermal resistance in plastics. Automotive parts, electrical insulators, and consumer goods use nylon for its mechanical properties and processability, enhancing performance and design flexibility. Its strength, chemical resistance, and versatility make nylon essential in modern applications of manufacturing.

What Are the Main Challenges in Manufacturing PA Plastic?

The main challenges in manufacturing PA plastic are listed below.

- Complex Polymerization Process: The synthesis of polyamide requires precise control over temperature, catalysts, and reactant ratios to achieve consistent molecular weight and chain structure. Variations during polymerization affect mechanical properties and lead to inconsistencies in product performance.

- High Production Costs: The cost of raw materials and energy-intensive processing contributes to elevated manufacturing expenses. The financial demands limit its use in cost-sensitive applications and require careful budgeting in large-scale production.

- Moisture Absorption Sensitivity: Polyamide absorbs water from the environment due to its polar molecular structure, which alters its mechanical strength and dimensional stability. The behavior complicates storage, handling, and processing, requiring pre-drying and controlled conditions.

- Dimensional Instability: Exposure to humidity and temperature fluctuations causes expansion or contraction in polyamide components. The modifications decrease accuracy in applications where tight tolerances and consistent fit are essential.

- Processing Temperature Demands: High melting points and narrow processing windows demand specialized equipment and strict thermal control during molding. Deviations in temperature lead to incomplete fusion, surface defects, or internal stress.

- Post-Processing Requirements: Components made from polyamide often require annealing or conditioning to stabilize properties and reduce internal stress. The additional steps increase production time and complexity.

- Chemical Reactivity During Fabrication: Polyamide reacts with certain additives and processing agents, which affects compatibility with colorants, flame retardants, or reinforcing fillers. The reactivity constrains formulation options and requires meticulous choice of additional materials.

- Tooling Wear and Maintenance: The abrasive nature of reinforced polyamide grades accelerates wear on molds and tooling surfaces. Frequent maintenance and replacement increase operational costs and reduce equipment lifespan.

How Does Nylon Material Affect the Quality of Products?

Nylon material affects the quality of products by delivering a combination of durability, tensile strength, and resistance to surface wear. The molecular structure supports long-term mechanical performance under stress, which contributes to consistent reliability across various conditions. Products made with nylon maintain shape and function through repeated use, reducing the likelihood of premature failure or deformation. Nylon provides elasticity and abrasion resistance in textile applications, which supports comfort and longevity in garments and industrial fabrics. Automotive components benefit from nylon’s ability to withstand vibration, heat, and mechanical load without compromising structural integrity. Medical devices rely on nylon for its balance of flexibility and strength, which allows for precise movement and sustained performance in sensitive environments. The material’s adaptability across industries reflects its role in improving product function, lifespan, and user experience.

What Are the Advantages of Polyamide Material?

The advantages of the Polyamide material are listed below.

- High Tensile Strength: Polyamide resists stretching and breaking under load due to its strong molecular bonds and semi-crystalline structure. The property supports its use in mechanical components, structural parts, and tension-bearing applications.

- Excellent Abrasion Resistance: The surface of polyamide withstands repeated contact and friction without significant wear. The durability makes it suitable for gears, bushings, and textile fibers exposed to movement and mechanical stress.

- Chemical Stability: Polyamide offers good resistance to oils and fuels, enabling reliable performance in automotive and industrial systems. However, prolonged exposure to strong acids, bases, or certain polar solvents should be avoided to preserve its mechanical integrity.

- Flexibility: The polymer chains in polyamide allow for controlled movement and deformation without cracking. The flexibility supports its use in textiles, cable insulation, and molded parts requiring impact absorption.

- Thermal Resistance: Polyamide tolerates moderately high temperatures, typically up to 120–180 °C depending on the grade, while retaining most of its mechanical strength and shape. This makes it suitable for components near heat sources such as engine compartments and electrical housings.

- Dimensional Stability: Polyamide retains its form under mechanical load and thermal cycling when properly conditioned. The stability ensures consistent fit and function in precision-molded parts and assemblies.

- Fatigue Resistance: Repeated stress does not easily degrade polyamide’s mechanical properties. The resilience supports its role in moving components, load-bearing structures, and dynamic systems.

- Lightweight Composition: Polyamide offers strength without excessive mass, reducing weight in assembled products. The benefit contributes to fuel efficiency in vehicles and ease of handling in consumer goods.

What Are the Disadvantages of Polyamide Material?

The disadvantages of the Polyamide material are listed below.

- Moisture Sensitivity: Polyamide absorbs water from the environment due to its polar molecular structure, which affects its mechanical properties. Increased moisture content reduces tensile strength and dimensional stability, leading to performance fluctuations in humid conditions.

- Difficult Recycling Process: Polyamide can be mechanically recycled, but additives, glass fibers, and moisture sensitivity can reduce quality after multiple cycles. These factors make recycling more complex compared to simpler thermoplastics.

- Higher Production Costs: The synthesis and processing of polyamide require more energy and specialized equipment compared to lower-cost plastics (polyethylene). The demands result in higher material expenses and increased operational costs for manufacturers.

- Thermal Degradation Risk: Prolonged exposure to high temperatures in air can cause oxidation and chain breakdown, leading to discoloration and reduced strength. Proper material selection and stabilization minimize this effect in high-heat environments.

- Shrinkage During Molding: Polyamide exhibits notable shrinkage when cooled after molding, which affects dimensional accuracy. The behavior requires precise tooling and process control to maintain consistent part geometry.

- Limited UV Resistance: Unmodified polyamide degrades under ultraviolet light, leading to surface cracking and loss of strength. Outdoor applications demand stabilizers or coatings to prevent premature aging.

- Chemical Reactivity with Acids: Polyamide reacts with strong acids, which compromises its structural integrity in corrosive environments. The limitation restricts its use in chemical processing systems where acid exposure is frequent.

- Surface Finish Challenges: Achieving a smooth surface finish with polyamide can be challenging because of its semi-crystalline structure and moisture absorption. Controlled molding and surface treatments help improve finish quality where aesthetics or precision are critical.

What Are the Properties of Polyamide?

The properties of the Polyamide are listed below.

- High Tensile Strength: Polyamide resists deformation under tension due to its strong molecular bonds and semi-crystalline structure. The strength supports its use in load-bearing components and structural applications requiring mechanical reliability.

- Low Friction Coefficient: The surface of polyamide allows smooth movement against other materials with minimal resistance. The property reduces wear in sliding parts and supports efficient mechanical operation.

- Resistance to Abrasion: Polyamide maintains surface integrity under repeated contact and mechanical stress. The durability extends product lifespan in environments involving friction and movement.

- Chemical Resistance: Polyamide withstands exposure to oils, fuels, and many industrial solvents without degrading. The stability supports its use in chemically active settings and fluid-handling systems.

- Moisture Absorption: The polar nature of polyamide causes it to absorb water from the environment, affecting its mechanical properties. Increased moisture content leads to dimensional changes and reduced strength in humid conditions.

- Thermal Stability: Polyamide retains its shape and mechanical performance across a wide temperature range. The heat resistance supports its use in engine compartments and electrical housings.

- Impact Resistance: Polyamide absorbs energy from sudden forces without cracking or breaking. The toughness supports its role in protective casings and dynamic mechanical systems.

- Dimensional Stability: Polyamide maintains consistent geometry under mechanical load and thermal cycling when properly conditioned. The stability ensures reliable fit and function in precision-molded parts.

What Is the Density of Polyamide?

The density of Polyamide typically ranges from about 1.12 to 1.16 grams per cubic centimeter, depending on the grade and level of glass reinforcement. The moderate density supports a balance between mechanical strength and lightweight composition, which contributes to its effectiveness in structural and load-bearing applications. Components manufactured from polyamide maintain durability without adding excessive mass, which benefits designs requiring strength-to-weight efficiency. The material’s density allows for reliable performance in automotive systems, consumer products, and industrial assemblies where weight reduction and mechanical integrity are essential.

What Is the Melting Point of Polyamide?

The melting point of Polyamide is from 220°C to 270°C, with variations based on the specific formulation and molecular structure. Polyamide has a melting point suitable for high-temperature applications. The thermal range supports reliable performance in environments where sustained heat exposure occurs during operation or processing. The ability to maintain structural integrity at elevated temperatures makes polyamide a preferred material in automotive systems, electrical housings, and industrial machinery. Components manufactured from polyamide resist deformation and mechanical failure when subjected to thermal cycling, frictional heat, or proximity to engines and heating elements. The combination of heat resistance and mechanical strength defines its role in applications requiring long-term durability under thermal stress.

What Is the Chemical Formula of Polyamide?

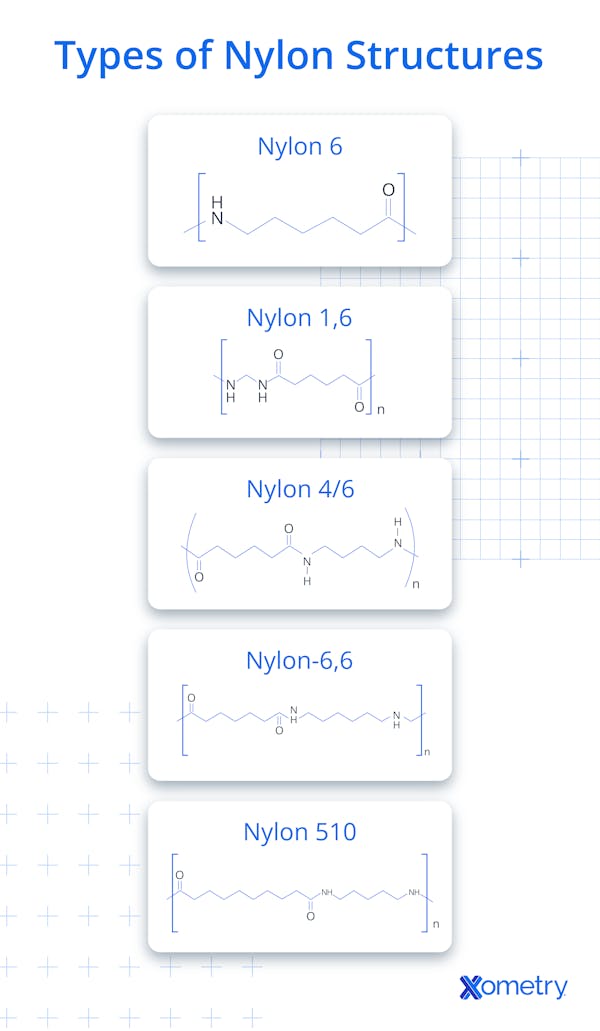

The repeating-unit formula depends on the type of Polyamide: for nylon 6 it is (C₆H₁₁NO)n, and for nylon 6,6 it is (C₁₂H₂₂N₂O₂)ₙ, where the subscript “n” indicates the repeating units within the polymer chain. Each unit contains six carbon atoms, 11 hydrogen atoms, one nitrogen atom, and one oxygen atom, forming a structure that supports strong intermolecular bonding. The presence of the amide group within each repeating segment contributes to the material’s mechanical strength, thermal resistance, and ability to form hydrogen bonds. The structural arrangement allows polyamide to maintain durability under stress and resist deformation in demanding environments. The consistent repetition of the amide linkage defines the polymer’s identity and influences its performance across industrial, textile, and engineering applications.

What Is the Structure of Polyamide?

The structure of Polyamide consists of repeating amide bonds formed through the reaction of diamines and dicarboxylic acids. Each repeating unit contains a carbonyl group linked to a nitrogen atom, creating a backbone that supports strong intermolecular forces. The presence of hydrogen bonding between chains contributes to the material’s mechanical strength and resistance to deformation. The linear arrangement of the polymer chains allows for controlled flexibility without compromising structural integrity. The molecular configuration supports thermal stability by resisting breakdown under elevated temperatures. The combination of bond strength, chain alignment, and intermolecular interactions defines the durability and performance of polyamide in demanding environments.

What Is Polyamide Used for?

Polyamide is used for various industries (textile, automotive) because of its mechanical strength, flexibility, and resistance to wear. The material forms durable fibers that support clothing, upholstery, and industrial fabrics in textile manufacturing. Engineering plastics rely on polyamide for components such as gears, bushings, and bearings that require consistent performance under mechanical stress. Automotive systems use polyamide for under-the-hood components, fasteners, and safety features that require thermal stability and impact resistance. Its capacity to retain shape and performance under pressure makes it suitable for electrical housings, consumer products, and industrial machinery. Every application leverages the polymer’s durability and dependable long-term performance in challenging settings.

Which PA Materials Are Used for Medical Applications?

The PA materials that are used for medical applications are sutures, implantable components, and prosthetic devices. Polyamide (PA) is used because of its strength, biocompatibility, and structural reliability. Its molecular structure resists degradation from bodily fluids and sterilization. Polyphthalamide supports medical uses due to its dimensional stability and chemical resistance, making it ideal for catheter tubing and personal care items.

Biocompatibility is essential when selecting materials for medical applications. Certain medical-grade polyamides are biocompatible and suitable for temporary contact or non-load-bearing implantable devices, but not all PA grades are approved for long-term implantation. Its strength and durability allow it to endure repeated stress and retain its shape over time. The qualities ensure polyamide's dependability in settings that demand consistent performance and safety. Its structural integrity, biological safety, and resistance to environmental factors establish polyamide as a trusted option for medical use.

Can Polyamide Be Used in Medical Implants?

Yes, polyamide can be used in medical implants under defined conditions. The material exhibits biocompatibility and mechanical strength suitable for non-load-bearing applications (surgical tools, catheter components, and temporary fixation devices). Its molecular structure supports resistance to wear and sterilization processes, which contributes to reliability in controlled medical environments. Polyamide does not degrade rapidly in biological settings, allowing for stable performance during short-term implantation. The balance between flexibility, chemical resistance, and dimensional stability makes polyamide a viable option for medical components that require precision without bearing continuous mechanical load.

What Are the Applications of Polyamide Material in Construction?

The applications of Polyamide material in construction are listed below.

- Durable Piping Systems: Polyamide supports fluid transport in construction through its resistance to pressure, abrasion, and chemical exposure. The material maintains structural integrity under varying temperatures and mechanical stress, which contributes to long-term reliability in plumbing and conduit systems.

- Electrical Insulation Components: Polyamide provides insulation in electrical housings, cable sheaths, and junction boxes due to its dielectric strength and thermal stability. The properties reduce the risk of electrical faults and support safe operation in residential and industrial settings.

- Structural Fasteners and Anchors: Polyamide is used in wall plugs, clips, and mounting brackets where mechanical strength and dimensional stability are required. Its resistance to impact and environmental stress supports secure fastening in concrete, masonry, and drywall installations.

- Protective Casings and Covers: Polyamide forms enclosures for sensors, switches, and control units exposed to dust, moisture, and vibration. The material’s toughness and resistance to surface wear maintain protection in outdoor and high-traffic environments.

- Window and Door Hardware: Polyamide supports hinges, rollers, and locking mechanisms through its balance of strength and flexibility. The components retain function under repeated use and exposure to temperature changes.

- Thermal Break Profiles: Polyamide separates interior and exterior metal frames in curtain walls and window systems to reduce heat transfer. Its relatively low thermal conductivity compared to metals and high dimensional stability contribute to energy efficiency in building envelopes.

- Construction Machinery Components: Polyamide is used in bushings, gear housings, and wear pads within construction equipment. The material withstands friction, load, and contamination, which supports operational reliability in demanding field conditions.

- Formwork Accessories: Polyamide forms spacers, ties, and alignment tools used in concrete casting and reinforcement placement. Its resistance to deformation and chemical exposure ensures consistent performance during curing and removal.

What Role Does PA Plastic Play in Automotive Safety Features?

The roles that PA plastic plays in automotive safety features are as an airbag housing and development systems, seatbelt components and tensioners, under-the-hood fasteners and clips, sensor casings and connectors, and brake system components. Crash-resistant interior panels, battery and fuse box enclosures, and cooling system support are other roles of PA plastic.

Polyamide supports airbag modules by maintaining structural integrity during rapid inflation and impact. Its resistance to heat and mechanical stress ensures reliable performance in critical moments. Polyamide forms guides, buckles, and tensioning mechanisms that require consistent strength under load. The material resists wear and deformation, which contributes to secure restraint during collisions. Polyamide withstands engine heat, vibration, and exposure to fluids without losing shape or strength. The properties support the stability of wiring harnesses and fluid lines in high-temperature zones.

Polyamide protects electronic sensors and connectors from moisture, vibration, and thermal cycling. The protection maintains accurate signal transmission and supports active safety systems. Polyamide is used in reservoirs, valves, and mounting brackets that require chemical resistance and dimensional stability. The material supports consistent fluid containment and mechanical function under pressure. Polyamide contributes to interior trim and support structures that absorb impact energy. Its toughness and flexibility reduce injury risk by minimizing sharp breakage during collisions.

Polyamide insulates and shields electrical systems from heat and contamination. The insulation supports safe energy distribution and protects critical components from short circuits. Polyamide forms brackets and housings for radiators and fans exposed to thermal stress. Its resistance to deformation under heat contributes to stable cooling performance and engine safety.

What Are the Benefits of PA Plastic in Food Packaging?

The benefits of PA plastic in food packaging are listed below.

- Barrier Against Oxygen: Polyamide restricts oxygen transmission through its dense molecular structure, which helps slow oxidation and extend food shelf life. The property supports longer shelf life and maintains flavor stability during storage.

- Moisture Resistance: The material limits moisture penetration, which prevents spoilage and texture degradation in sensitive food products. The resistance contributes to consistent product quality across varying humidity conditions.

- Mechanical Strength: Polyamide withstands pressure, impact, and handling stress without tearing or puncturing. The durability ensures packaging remains intact during transportation and retail display.

- Thermal Stability: The polymer tolerates heat during sealing and sterilization without losing structural integrity. The stability supports hygienic packaging processes and maintains barrier performance under elevated temperatures.

- Flexibility for Film Applications: Polyamide adapts to multilayer film structures used in vacuum sealing and flexible pouches. The flexibility allows for secure sealing and efficient space utilization in packaging systems.

- Chemical Resistance: Polyamide offers reliable resistance to oils, fats, and most food ingredients, making it suitable for contact with a wide range of products. With proper stabilization, it also maintains integrity during cleaning and sterilization processes.

- Transparency and Gloss: Polyamide provides a clear and glossy surface that improves product visibility and presentation. The visual appeal supports consumer trust and enhances shelf impact.

- Recyclability in Select Formats: Certain grades of polyamide used in food packaging allow for mechanical recycling when properly sorted. Recyclability depends on local recycling infrastructure, supporting sustainability goals in regulated waste management systems.

“When choosing polyamide, think beyond strength, consider moisture, heat, and chemistry. The best designs balance PA’s toughness and precision with the right grade and conditioning to unlock its full performance.”Audrius Zidonis, Principal Engineer at Zidonis EngineeringNote from the Editor

What Is the Cost of Polyamide Plastic Compared to Other Plastics?

The cost of Polyamide plastic ranges from about $2.50 to $4.00 per kilogram, which is higher than polyethylene and polypropylene, priced around $1.00 to $1.50 per kilogram. The elevated cost of polyamide results from its complex polymerization process, energy-intensive production, and additional conditioning requirements. Compared to polyethylene and polypropylene, polyamide demands more precise control during synthesis and molding, which increases operational expenses across manufacturing stages. The pricing difference reflects the material’s superior mechanical properties, including tensile strength, abrasion resistance, and thermal stability. Polyamide supports applications requiring long-term durability, dimensional accuracy, and resistance to environmental stress. While the initial investment in polyamide exceeds that of lower-cost plastics, the material’s performance characteristics reduce maintenance frequency and extend product lifespan. The trade-off between cost and reliability positions polyamide as a preferred choice in automotive systems, industrial components, and engineered assemblies where structural integrity and thermal endurance are critical.

How is PA Plastic Recycled?

PA Plastic is recycled through a process that begins with the collection of post-industrial or post-consumer waste. The material is sorted by type and grade to ensure compatibility during reprocessing. Polyamide (PA) is cleaned, shredded, and typically re-extruded into pellets for reuse, but repeated melting can shorten molecular chains and lower mechanical strength. The recycling of PA presents challenges due to its strong hydrogen bonding and moisture sensitivity, which affect thermal stability and mechanical properties during reprocessing. Developments in compatibilizers, purification methods, and chemical recycling techniques aim to improve the recyclability of PA by tackling degradation and contamination problems. The advancements help recover high-performance materials from waste streams while preserving product quality.

Is Polyamide (PA) More Resistant to Environmental Stress Cracking than Acrylonitrile Butadiene Styrene (ABS)?

Yes, Polyamide (PA) generally resists environmental stress cracking better than acrylonitrile-butadiene-styrene (ABS), although it can still crack when exposed to certain chemicals or moisture cycling. The molecular structure of PA has strong hydrogen bonding and a semi-crystalline arrangement, which contributes to its durability under mechanical stress and exposure to chemicals. ABS has an amorphous structure with lower chemical resistance, making it more vulnerable to cracking when subjected to stress in aggressive environments. Polyamide outperforms ABS under stress due to its ability to withstand mechanical load and chemicals, maintaining integrity. ABS degrades and cracks with solvents or stress changes, making it less reliable. PA's toughness and moisture absorption help dissipate stress better than ABS's rigidity. Material properties (molecular arrangement, chain mobility, and intermolecular forces) influence stress cracking resistance. PA's flexible backbone and crystalline regions help distribute stress, reducing strain. The material properties of Acrylonitrile Butadiene Styrene (ABS) with rigid styrene-acrylonitrile segments accumulate stress faster, causing cracks. Flexibility and cohesive energy density are key in a polymer's response to environmental and mechanical stresses.

Does Polyamide (PA) Have Better Moisture Absorption Properties than High-Density Polyethylene (HDPE)?

Yes, Polyamide (PA) absorbs far more moisture than high-density polyethylene (HDPE) because of its polar amide groups. The molecular structure of PA includes polar amide groups that attract and retain water molecules from the surrounding environment. HDPE features a non-polar, highly crystalline structure that effectively resists moisture penetration and exhibits low water absorption under typical conditions. PA absorbs more moisture because of its hygroscopic nature, causing dimensional changes and altering mechanical properties over time. HDPE stays stable in humid or wet environments with minimal changes in stiffness, strength, or shape. The absorption differences affect each material's performance during storage, processing, or use. Moisture absorption impacts PA by lowering tensile strength and increasing flexibility, which is advantageous or problematic based on application needs, while High-Density Polyethylene (HDPE) performs reliably outdoors, in marine, and packaging settings due to its water and chemical resistance. A material's ability to retain or repel moisture impacts its appropriateness for structural, electrical, or barrier applications.

Is Polyamide (PA) More Suitable for High-Performance Textiles than Polyethylene (PE)?

Yes, Polyamide (PA) is more suitable for high-performance textiles than Polyethylene (PE). The molecular structure of PA offers higher tensile strength, elasticity, and abrasion resistance, vital for textiles under mechanical stress. Polyamide performs more reliably in textile environments that require consistent mechanical performance and resistance to wear. Its ability to maintain strength under tension and recover from deformation contributes to its widespread use in garments, industrial fabrics, and technical textiles. Polyethylene does not possess the same level of resilience and flexibility, which makes it less suitable for applications that need durability and shape retention. PE does not provide the same balance of strength and flexibility required for demanding textile functions, while being lightweight and chemically stable. The benefits of PA in the textile industry include extended product lifespan, reduced material fatigue, and improved comfort through adaptive stretch. Its moisture management and thermal stability support performance in varied conditions, while its resistance to tearing and surface damage ensures reliability across multiple use cycles. Cost efficiency and chemical resistance provide advantages, but mechanical properties fall short of high-performance textile standards in Polyethylene (PE).

Does Polyamide (PA) Offer Better Wear Resistance than High Impact Polystyrene (HIPS)?

Yes, Polyamide (PA) offers better wear resistance than High-Impact Polystyrene (HIPS). The molecular structure of PA includes strong intermolecular bonds and a semi-crystalline arrangement, which contribute to its ability to withstand repeated surface contact and mechanical stress. Polyamide maintains surface integrity under dynamic loading and contact with rough materials, suitable for environments concerned with mechanical wear. High-Impact Polystyrene has an amorphous structure with lower toughness, making it more prone to surface degradation when exposed to continuous friction or abrasive forces. Impact resistance remains high, but tensile strength and surface durability decrease under long-term abrasive exposure in Polystyrene (HIPS). The wear resistance difference is notable in applications with moving parts, sliding contact, or repeated mechanical interaction. Wear resistance is key to material lifespan, maintenance, and reliability. It prevents surface failure, maintains dimensions, and ensures function under mechanical load. In high-friction environments, resisting surface damage influences material choice.

Is Polyamide (PA) More Compatible with Metal Plating than Polylactic Acid (PLA)?

Yes, Polyamide (PA) is more compatible with metal plating than Polylactic Acid (PLA). Polyamide has polar groups that aid surface activation and adhesion during plating. Polylactic Acid is less polar and biodegradable, which struggles with uniform metal deposition and adhesion. PA maintains stability and resistance during plating, while Polylactic Acid (PLA) degrades or deforms. Polyamide (PA) bonds better with metals due to surface energy and pretreatment compatibility, without structural impact. PLA lacks thermal and chemical resilience for reliable plating, limiting its use in durable finishes. The differences affect coating reliability, feature precision, and lifespan. Material compatibility ensures better adhesion, surface uniformity, and delamination resistance, reducing failures and enhancing performance in different applications. Bond strength under stress is crucial for polymers in metal-plated parts.

Does Polyamide (PA) Have Better Barrier Properties Against Gases than Polystyrene (PS)?

Yes, Polyamide (PA) has better barrier properties against gases than Polystyrene (PS). PA's tightly packed chains and polar groups reduce gas permeation, while PS's amorphous, non-polar structure allows easier diffusion. Permeability differences stem from polymer density and polarity, affecting gas interaction. Polyamide shows lower transmission rates for oxygen, carbon dioxide, and other gases, making it better for containment and preservation. PS has less resistance, reducing effectiveness where gas exposure impacts product integrity. Reliability in packaging, barrier films, and coatings depends on the ability to restrict gas flow, which is better achieved with polymers like Polyamide (PA), while Polystyrene (PS) is less effective in applications. Gas barrier properties are vital for extending shelf life, preventing contamination, and ensuring chemical stability. Low-permeability materials help store sensitive items, reduce spoilage, and keep controlled atmospheres. The choice of polymers for packaging and coatings depends on their ability to resist gas diffusion under stress.

Is Polyamide (PA) More Cost-Effective for Manufacturing Thin-Walled Parts than Polypropylene (PP)?

No, Polyamide (PA) is not more cost-effective for manufacturing thin-walled parts than Polypropylene (PP). The production of thin-walled components favors PP due to its lower raw material cost and simplified processing requirements. PA demands higher energy input during molding and presents greater sensitivity to moisture, which increases handling complexity and operational expense. Polyamides support reduced tooling wear and contribute to durability in high-performance applications, though they do not support faster cycle times compared to materials like polypropylene. It delivers superior mechanical strength and thermal stability, which benefits designs requiring long-term durability and load-bearing capacity. Polypropylene offers economic advantages in applications where structural demands remain moderate and chemical resistance is prioritized. The trade-off between cost and performance becomes evident when selecting materials for housings, enclosures, or lightweight structural parts. Polyamide (PA) meets functional requirements under mechanical stress, creating a balance between affordability and engineering reliability, while Polypropylene (PP) satisfies budget constraints.

Does Polyamide (PA) Perform Better in Gear Applications than Polybutylene Terephthalate (PBT)?

Yes, Polyamide (PA) performs better in gear applications than Polybutylene Terephthalate (PBT). The mechanical structure of PA supports higher wear resistance, greater toughness, and stronger load-bearing capacity, which contribute to its reliability in gear systems exposed to continuous motion and contact stress. PBT lacks the same level of durability under repeated friction and mechanical pressure, while being dimensionally stable and resistant to moisture. Polyamide maintains surface integrity and structural cohesion in environments involving rotational force and sliding contact. Its ability to absorb impact and distribute stress across gear teeth reduces the risk of fatigue and deformation. Lower abrasion resistance and reduced toughness lead to faster wear in high-load conditions, limiting long-term performance in dynamic assemblies when using Polybutylene Terephthalate (PBT). PA's suitability for mechanical components under friction and pressure stems from its semi-crystalline structure, which dissipates energy and maintains surface resilience. Its chain flexibility, thermal endurance, and cohesive strength allow it to perform well in gear housings, transmissions, and load-bearing assemblies. The combination of mechanical strength, wear resistance, and stability under stress makes polyamide ideal for precision gear applications.

Is Polyamide (PA) More Resistant to High Voltage than Acetal (POM)?

Yes, Polyamide (PA) generally maintains electrical insulation more effectively than acetal (POM) at elevated temperatures. The molecular structure of PA, with polar amide groups and a semi-crystalline network, allows it to withstand electrical stress and retain insulation under heat and load. POM offers high dielectric strength in dry conditions but loses insulating performance more rapidly as temperature increases, despite its excellent mechanical stability and moisture resistance. Polyamide maintains its insulating properties across a broader range of temperatures and frequencies, which supports its use in components exposed to fluctuating electrical loads. Electrical resistance plays a critical role in the performance of connectors, insulators, and housings used in power distribution and electronic assemblies. Materials with higher dielectric strength reduce the risk of arcing, short circuits, and thermal degradation. PA supports long-term reliability in environments where voltage stability and insulation integrity determine operational safety and product lifespan. The ability to resist electrical stress without compromising mechanical structure defines the suitability of Polyamide (PA) and Acetal (POM) for high-voltage applications.

Summary

This article provided a summary of the uses, properties, types, and advantages of nylon as a material for use in product and part fabrication.

Xometry offers injection molding services for all of your prototyping and production needs. Visit our website to learn more and to request a free, no-obligation quote using our Instant Quote Engine.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.