Plastic is pretty much everywhere today, and that’s because it has many qualities that manufacturers—many of our customers included—really value, like durability, low cost, and ease of production. At Xometry, we often use CNC machining, 3D printing, and other methods to manufacture thousands of plastic parts. There’s a lot to know about plastic, though. There are many different types, each one good for a different use. Let’s have a look at this common manufacturing material in more detail.

What Exactly Is Plastic?

Plastic is a synthetic or semi-synthetic material that usually comes from petrochemicals or things like cellulose and starch. Certain types of plastic are known as resins. To make plastic, the main components are chemically treated until they make polymers, which are basically long chains of molecules. These can be molded using popular methods like extrusion or injection molding.

Plastic requires lots of different polymers and materials, both artificial and natural. It’s made using several raw materials, and some of them include natural gas, coal, starch, cellulose, crude oil, and even salt. You can make plastic in one of two ways: polymerization or polycondensation.

Plastic is pretty much everywhere today, and that’s because it has many qualities that manufacturers, many of our customers included, really value—like durability, low cost, and ease of production. That goes for both thermoplastics and thermosets, the two main categories. One of the main differences between the two is that the former can be remolded after it’s been melted, but the latter can’t be reworked again when heated.

Plastic is huge among Xometry customers and is used in toys, electronics, automotive, packaging, and medical devices. It continues to be popular, mainly because it has characteristics that are still hard to find in other materials, like being lightweight, flexible, non-conductive, and not requiring a ton of energy to make. For medical devices, plastics are sterile and biocompatible while easy to mold.

What Is the History of Plastic?

The discovery of plastic dates back to 1839, when Charles Goodyear discovered a way to make rubber more resilient and elastic via a process called vulcanization. During this time, he also made one of the first-ever polymer mixtures. Then, in 1855, Alexander Parkes discovered celluloid, which is a combination of camphor/lime and cellulose nitrate and is also known as Parkesine.

Celluloid was the first thermoplastic that would become flexible when heated and hard again when cooled down. After this, there were several advancements in the world of plastics, such as Victor Regnault’s isolation of PVC in 1835, the creation of the first synthetic polymer (industrial plastic) by John Wesley Hyatt in 1869, and Edward Brandenberger’s introduction of transparent food packaging in 1900.

What Is Plastic Made Of?

Many polymers, both artificial and natural, are used to make plastics. Coal, natural gas, cellulose, starch, crude oil, and salt are a few of the most common constituents in the production of plastic. The polymerization and polycondensation processes, which both require specific catalysts, are the main methods for producing plastics. In a polymerization reaction, monomers such as propylene and ethylene are joined to form long polymer chains. Each polymer has a distinct size, structure, and set of properties that depend on the different basic monomers involved.

What Are the Characteristics of Plastic?

Plastic is extremely versatile, and that’s why so many manufacturers around the world prefer it to other materials. It’s available in lots of colors and textures, and it can be molded into almost any shape you want. Unlike many other materials, it can also be made transparent, like the plastic used in disposable water bottles. As far as textures go, plastic is available in almost any variation, from smooth and shiny to rough and matte. And some can even be flexible. The image below shows a custom plastic part we made at Xometry using injection molding:

What Is the Color of Plastic?

Plastic, or resin, is nearly colorless or milky-white and can be colored by adding colorants or pigments.

What Does a Plastic Look Like?

Plastic can come in many different colors and textures, depending on the type of plastic and how it has been treated or processed. Plastic is a synthetic polymer made from various organic materials that can be molded into almost any shape. Some types of plastic are clear and transparent, like that used in disposable water bottles, while others are opaque and available in a range of colors. Plastic can also have different surface textures, ranging from smooth and shiny to rough and matte. Some types of plastic have soft and flexible textures, while others are rigid.

What Are the Different Types of Plastic?

There are lots of different types of plastic available today, most of which we offer at Xometry. We’ve listed some of these below:

1. Polyethylene Terephthalate (PET)

This is the most popular thermoplastic resin in the polyester group and is the most produced synthetic plastic. Some of the reasons PET has hit first place are because it’s easy to recycle, resistant to water and organic compounds, has a high strength-to-weight ratio, and is almost shatterproof. That’s why it’s found almost everywhere from food containers to garment fibers.

2. Acrylonitrile Butadiene Styrene (ABS)

ABS is also very popular and is made by polymerizing styrene and acrylonitrile with polybutadiene. Many of our customers like ABS because it’s flexible, easy to work with, strong, and resistant to impact. Because it’s relatively inexpensive, ABS can often be found in various items within the automotive and refrigeration industries, as well as protective headgear, luggage, and children’s toys. We have a whole guide on ABS if you’d like to find out more. The following image shows some ABS parts that were 3D printed here at Xometry:

3. Polyvinyl Chloride (PVC)

PVC is the third most common synthetic plastic polymer, and it’s available in both flexible and rigid variations, making it really versatile. Foamed PVC sheets, for instance, are often found in in-store displays, exhibits, and kiosks, and you’ll see rigid PVC everywhere, too, from construction materials to windows, to bottles, to non-food packaging. More flexible and softer versions of PVC can actually be found in clothing, as well as plumbing supplies, and medical tubing because of added phthalates and other plasticizers. The following image shows an example of PVC:

4. Polypropylene (PP)

Polypropylene is the second most produced synthetic plastic and classifies as a thermoplastic polymer. It’s a hit among Xometry customers largely because of how flexible it is. Despite that, it still manages to be surprisingly strong. That’s why PP sheets are used for things like food containers, medical devices, automobile components, and laboratory equipment. It also helps that they’re affordable and resistant to heat and acid.

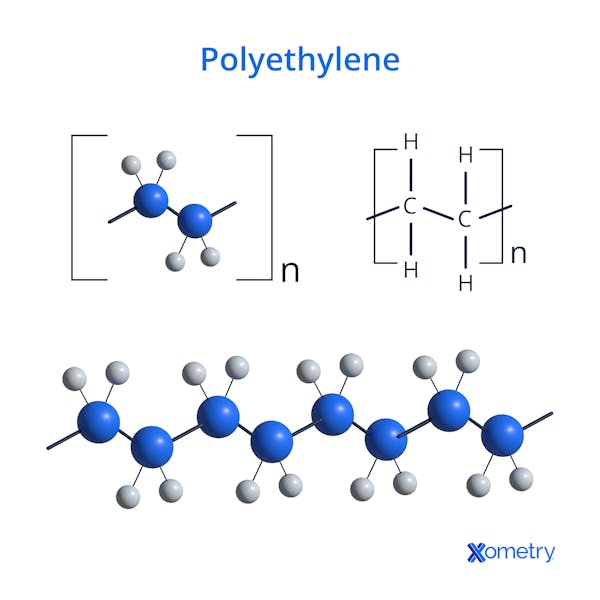

5. Polyethylene (PE)

Now we move to the most common plastic on the planet; polyethylene (PE). This material comes in several densities, and you can see a breakdown of its molecular structure:

LDPE (low-density PE) is ductile and obviously low in density, and that’s why it’s popular for items like shopping bags, disposable packaging, and transparent food containers. We’ve put together a whole guide on low-density polyethylene if you’d like to find out more.

MDPE (medium-density PE) is used in things like gas pipes, shrink film, and carrier bags because of its medium density.

HDPE (high-density PE) is way more robust than the other types, and that makes it a perfect fit for things like snowboards, sewer piping, boat hulls, and folding chairs. Our guide on high-density polyethylene provides much more detail on this.

UHMWPE (ultra-high-molecular-weight PE), though not much denser than HDPE, is more resistant to abrasion because of its huge polymer chains. That’s why you’ll often come across this plastic in bearings, artificial ice skating rinks, and even hip implants (it has low friction while remaining rather dense).

6. Polystyrene (PS)

Often referred to as Styrofoam, polystyrene can be solid and foamed. You’ll come across it in day-to-day items like egg cartons, disposable dinnerware, and drinking cups, and that’s mainly due to the fact it’s yet another type of plastic that’s cheap and easy to produce. Here’s a not-so-fun fact to remember, though: it’s extremely combustible and releases toxic chemicals when heated.

7. Acrylic or Polymethyl Methacrylate (PMMA)

Acrylic is used all the time in optical products and gadgets because it’s relatively easy to produce and work with, as well as transparent, lightweight, and resistant to breakage. Sheets of it are also used for mirrors and plexiglass. PMMA is very popular because it has some unique characteristics, one of them being that it’s resilient against projectiles. What’s more, it resists UV rays and static electricity, and is compatible with bright dyes. As a bonus, it’s over fifteen times more impact-resistant than glass and polycarbonate sheeting combined. You can visit our guide on PMMA for more information.

8. Polycarbonate (PC)

Polycarbonate is strong, stable, and transparent; hence it’s a favorite when it comes to engineering purposes. One of its most impressive features is that its strength-to-weight ratio is 250 times better than steel’s, and it’s as clear as glass. That’s tough to beat. Transparent sheets of this stuff can be 30 times stronger than acrylic and surprisingly easy to work with. They’re also not difficult to mold or form (thermo-form or cold-form). Another characteristic of PC that many of Xometry’s customers love is the fact that this material can be cut right away without the need to be pre-formed and manufactured. Police riot gear, greenhouses, CDs, and sunglasses are just some common things often made using polycarbonate. We have a guide on it if you’d like to learn more. This image shows a 3D-printed sample using polycarbonate:

| Property | Description |

|---|---|

Property Density | Description They can be as low as 0.9g/cm³ for foamed plastics and as high as 1.5g/cm³ for some engineering plastics. |

Property Melting point | Description This varies greatly depending on the type of polymer. LDPE, for instance, can melt around 105°C and PET at around 250°C. |

Property Hardness | Description Another factor that varies significantly. Some can be soft and flexible, and others can be hard and rigid, depending on the polymer and processing. |

Property Transparency | Description Some are transparent, and others are opaque and can block light. Many transparent plastics can accept dye if you want to make them opaque. |

Property Permeability | Description They can be permeable to gasses and liquids, which is good for food packaging, but not so much for things like chemical storage. |

Property Chemical resistance | Description Many plastics are resistant to industrial chemicals and acids, as well as other types of corrosive substances. |

Property Stability | Description Some can be sensitive to heat, as well as light and radiation, which could cause them to eventually degrade. You could always add some UV stabilizers and antioxidants to make some plastics more stable. |

Property Flammability | Description Many plastics are highly flammable and toxic when burned, but sometimes flame retardants can be added to make them a little more fire-resistant. |

Property Degradation | Description Plastics degrade at different rates, and this depends on the type and conditions, among other things. For instance, PE and PP can take hundreds of years to degrade, but PLA is biodegradable and, when exposed to heat, moisture, and microorganisms, can break down rather quickly. Some plastics can crack and fragment, even if they don’t break down chemically, but this will release microplastics into the environment, which is not good. |

Property Solubility | Description Amorphous plastics (polystyrene, polycarbonate) are more soluble in organic solvents than crystalline ones. Some highly crystalline polymers like nylon and polyolefin are resistant to dissolution, but others like PVA are easily soluble in water. |

Property Reactivity | Description This depends on the chemical makeup. Polyethylene, for instance, can form carbon dioxide and water when reacting with oxygen, but polypropylene tends to be stable and unreactive in most situations. |

Property Biodegradability | Description Some are, and some aren’t. Polyethylene is not biodegradable and can lay around for hundreds of years, but something like polycaprolactone (PCL) is and can be broken down by bacteria and fungi. |

Property Recyclability | Description Some types are easier to recycle than others, and not all require the same method. The main issue with recycling plastic is that they all have different properties. |

Plastic Properties

What Are the Physical Properties of Plastic?

The physical properties of plastic include:

- Density: Plastics come in many different densities, from as low as 0.9 g/cm³ for foamed plastics to as high as 1.5 g/cm³ for some engineering plastics.

- Melting Point: The melting points of plastics vary widely depending on the type of polymer. Some plastics have low melting points and can be easily molded while others have high melting points and require specialized processing techniques.

- Hardness: Plastics can range from soft and flexible to hard and rigid, depending on the specific polymer and its processing.

- Transparency: Some plastics are optically transparent while others are opaque and block light. Many transparent plastics can accept dye if you need them to be opaque.

- Permeability: Plastics can be permeable to gasses and liquids, which can be an advantage in some applications (such as food packaging) and a disadvantage in others (such as chemical storage).

What Are the Chemical Properties of Plastic?

Here are some common chemical properties of plastic:

- Resistance to Chemicals: Many types of plastic are resistant to industrial chemicals, acids, and other corrosive substances. This makes them useful in a variety of industrial applications.

- Stability: Some plastics are sensitive to heat, light, and radiation, which can cause them to degrade over time. UV stabilizers and antioxidants are often added to plastics to improve their stability.

- Flammability: Plastics can be highly flammable, and many of them release toxic gasses when burned. Flame retardants are often added to plastics to improve their fire resistance.

- Degradation: The rate at which plastics degrade depends on a variety of factors, including the type of plastic, the conditions to which they are exposed, and the specific environmental factors they encounter. Some plastics, such as polyethylene (PE) and polypropylene (PP), degrade very slowly so they will persist in the environment for hundreds of years. Other plastics, such as polylactic acid (PLA), are designed to be biodegradable and can break down much more quickly when exposed to moisture, heat, or microorganisms. Some plastics can undergo physical degradation, such as cracking or fragmentation, even if they do not break down chemically. This can be caused by sunlight, temperature changes, or mechanical stress, and can lead to the release of hazardous plastic particles called microplastics into the environment.

- Solubility: Each plastic has unique solubility characteristics. Plastics that are amorphous (not crystalline), like polystyrene and polycarbonate, are more soluble in typical organic solvents than crystalline ones. Certain highly crystalline polymers, including nylon and polyolefin, resist dissolution while others like polyvinyl acetate (PVA) are highly soluble in water.

- Reactivity: Plastics can be reactive in different ways, depending on their chemical composition. For example, polyethylene reacts with oxygen to form carbon dioxide and water while polypropylene is relatively unreactive and stable in most chemical environments.

- Biodegradability: Some plastics, such as polyethylene, are not biodegradable and can persist in the environment for hundreds of years. Others, such as polycaprolactone (PCL), are biodegradable and can be broken down by bacteria and fungi over time.

- Recyclability: Plastics can be difficult to recycle since they each have different chemical compositions and properties. Some types of plastics are easier to recycle than others, and recycling methods vary depending on the type of plastic.

What Are the Applications of Plastic?

Plastic has many different applications. Some of the most common uses of plastic are listed below:

1. Toys

Plastics are often used in the production of toys because they can be molded into various shapes and colors. Plastic toys are durable and lightweight, so they withstand wear and tear.

2. Electronics

Plastics are non-conductive, meaning they can protect electronic components and allow for easy assembly. This is why you find plastic in computer and phone cases and as the insulation on wires.

3. Automotive

Plastics are used in various parts of automobiles, including dashboards, bumpers, engine parts, and interior panels. Since they’re both lightweight and durable, they reduce the vehicle’s weight and improve fuel efficiency.

4. Construction

In the construction sector, plastics are used in a growing array of applications. Plastics are economically appealing thanks to their outstanding strength-to-weight ratio, cost effectiveness, durability, low maintenance requirements, and corrosion resistance. Plastics are used in, among other things, pipes, insulation, roofing materials, and windows.

5. Textiles

Plastics can be turned into synthetic fibers and fabrics for textiles. Modern clothing and upholstery commonly include plastics.

6. Packaging

Plastic is an ideal material to use for product packaging. Plastics are adaptable, hygienic, light, flexible, and durable. Packaging is thus responsible for the majority of the plastics used globally, coming in the form of vending packaging, baby products, protective packaging, containers, bottles, drums, trays, boxes, cups, and much more.

7. Medical Devices

Plastics are used extensively in the medical industry, including, but not limited to, disposable syringes, IV and blood bags, prosthetic limbs, implantable devices, dialysis machines, heart valves, tubing, and wound dressing. Medical-grade plastics are sterile and biocompatible and can be easily molded into complex shapes. Plus, they’re often less expensive than traditional medical materials.

What Are the Advantages of Plastics?

Plastics have become so widespread because of their numerous advantages, including:

- Versatility: Plastics can be molded into various shapes and sizes.

- Durability: Plastics are strong and can withstand wear and tear, making them long-lasting and, in some cases, suitable for reuse.

- Lightweight: Plastics are generally lightweight. This makes them great when weight is an important consideration, such as in the automotive and aerospace industries.

- Cost-effectiveness: Plastics are often less expensive than other materials such as metals, making them a more cost-effective option for many applications.

- Ease of Manufacture: Plastics are easy to manufacture in large quantities, so they’re perfect for the sort of mass production that cuts per-unit costs.

- Low Energy Consumption: The production of some types of plastics requires less energy compared to the production of other materials. That, in turn, helps reduce the environmental impact of manufacturing.

- Safety: Plastics can be designed to be non-toxic and safe for use in the medical and food industries.

What Are the Disadvantages of Plastics?

Unfortunately, plastic has some major downsides. Probably the biggest issue with plastics is that most of them aren’t biodegradable and cause a buildup of pollution, which in turn harms wildlife and the rest of the environment. They’re also pretty hard to recycle. Another serious issue is that most types of plastic are petroleum-based, which means they’re not renewable. That makes them a contributing factor to our dependency on fossil fuels and the depletion of resources.

Frequently Asked Questions on Plastic

How Is Plastic Harmful?

Plastic is harmful for several reasons. Firstly, most plastic is not biodegradable and can remain in the environment for hundreds of years, causing plastic pollution.

Secondly, some plastic contains toxic chemicals such as bisphenol A (BPA) and phthalates that can leach out into the environment or contaminate food and water sources, posing health risks to humans and wildlife. Although research on the health effects of plastics is far from complete, current scientific findings do show that plastic causes diseases, disabilities, and early death at every stage of its life cycle. Beyond that, animals can become entangled in plastic debris or ingest it, leading to injury, suffocation, and death. Additionally, plastic pollution can alter habitats and food sources, leading to ecosystem disruptions.

The production of plastic uses non-renewable resources such as petroleum, contributing to resource depletion and dependency on fossil fuels. And finally, the production, transportation, and disposal of plastic can contribute to greenhouse gas emissions and climate change, further adding to the harmful effects.

What Causes Plastic Waste?

Plastic waste is caused by improper disposal of used plastics. Faulty part designs can also result in plastic waste especially when the part cannot be used as planned.

Is Plastic Really Necessary?

The short answer here is that it depends. Sometimes there are no alternatives that are viable, economical, and accessible. In many cases, though, plastic can be replaced with more sustainable materials such as paper, glass, or metal. However, in some industries, such as medical devices, plastic’s unique properties are what make it useful. It is important to assess the need for plastic on a case-by-case basis and consider its environmental and health impacts before deciding whether it is truly necessary.

What Are Alternatives to Plastic?

Several alternatives to plastic are often viable depending on the item’s purpose. Here are some examples:

- Paper: Paper is a renewable, biodegradable, and recyclable material that can be used as an alternative to plastic in many applications such as in packaging, bags, and straws.

- Glass: Glass is a reusable and recyclable material that can be used as an alternative to plastic in bottles, jars, and containers.

- Metal: Metal is a durable and recyclable material that can be used in cans, containers, and utensils.

- Bioplastics: Bioplastics are made from renewable resources, such as corn starch, and are biodegradable or compostable. They can be used as alternatives to conventional plastics for such purposes as packaging and bags.

- Natural Fibers: Natural fibers, such as cotton and hemp, can be used as alternatives to plastic in textiles, bags, and packaging.

- Wood: Wood is a renewable and biodegradable material that can be used to make utensils and packaging.

- Bamboo: Bamboo is a specific type of wood that has gained popularity in recent years due to its sustainability and versatility. Bamboo is a quick-growing, renewable resource that may be harvested without doing any environmental harm. Some examples of how bamboo can be used as an alternative to plastic include: utensils, straws, packaging, textiles, and furniture.

What Is the Difference Between Polymer and Plastic?

Plastics and polymers are closely related concepts, but they are not the same thing. A polymer is a large molecule made up of repeating subunits called monomers, while plastic is a material made from polymers that can be molded into various shapes.

In short, plastics are made up of polymers, but not all polymers can be turned into plastics. Polymers can be natural or synthetic and take on many different forms including proteins, DNA, and cellulose. When the right polymers are chemically treated and processed, they can be turned into plastic.

While polymers exist in many forms, plastic is a specific type of polymer that is designed to be easily molded and shaped. Plastic is often used in packaging, consumer goods, automotive parts, and construction materials because it is lightweight, durable, and versatile.

So, in summary, polymers are large molecules made up of repeating subunits called monomers, while plastic is a material made from polymers that can be molded into various shapes.

How Xometry Can Help

If you have any questions about plastic, one of our Xometry representatives would be happy to help. Xometry also offers a wide range of manufacturing services, like CNC machining, 3D printing, laser cutting, and plastic injection molding. To get started as soon as possible, request a free no-obligation quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.