Blog

The latest Xometry product updates, news, and trends in manufacturing.

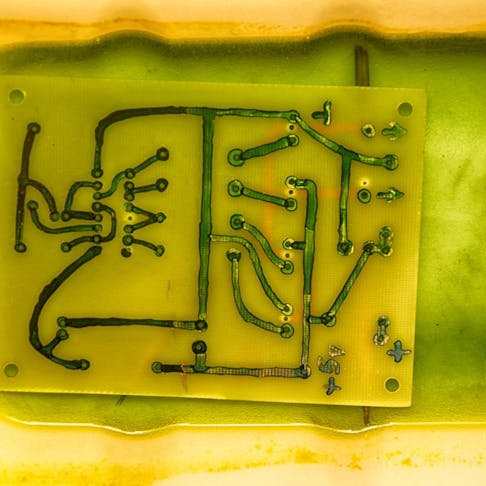

Dry Etching vs. Wet Etching - Differences and Applications

[Webinar Recording] Xometry: Your Medical Molding Partner from Prototype to Production

Sixty-Four Percent of Small Manufacturers Anticipate Growth as Business Confidence Rebounds to Pre-COVID Levels

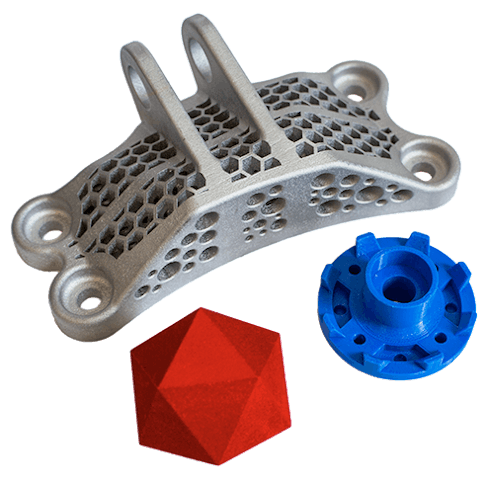

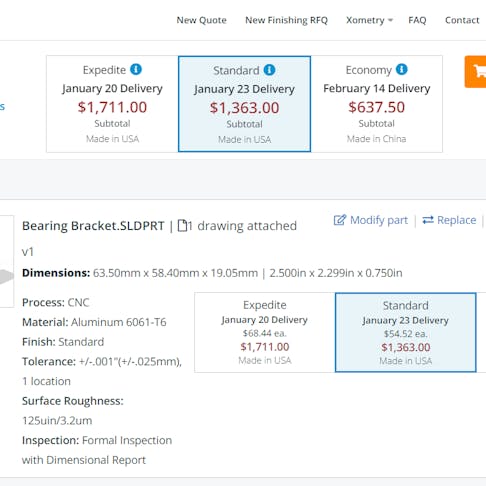

Product Update: New CNC Machining Materials and Metal Finishes Available for Instant Quoting

Podcast Roundup: Vol. 5, Sept. 2020 | MCAD Cafe, Advanced Manufacturing, and 5 More

Xometry Announces Recipients of the 2019 Excellence In Manufacturing Awards

Product Update: New Cast Urethane Materials and Finishes Available for Instant Quoting

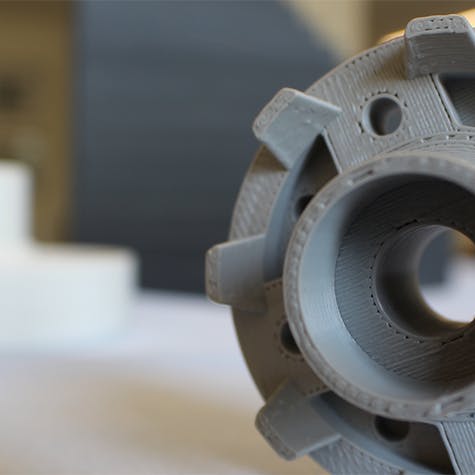

On-demand Webinar: A Deep Dive into SLS 3D Printing and High-Performance Materials

60% of Small Manufacturers Unlikely to Hire in Upcoming Quarter Citing Difficulty in Finding Skilled Employees

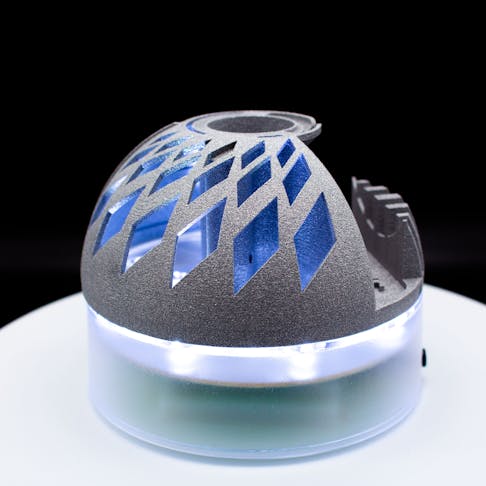

On-demand Webinar: Best Practices for Metal 3D Printing through Binder Jetting

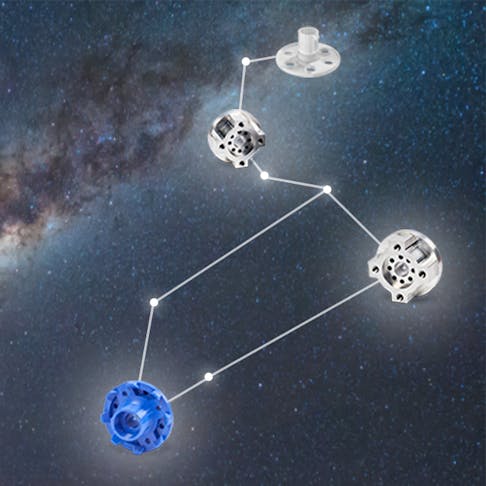

PA 12 - A High-Performance Material Perfect for Prototyping and Production

How To Mass Produce a Product: History, Process, Advantages, and Disadvantages

Manufacturing Explained Episode #2: Part 2, Explaining the Injection Molding Process with Scott Benson

Introducing the Manufacturing Explained Podcast! Episode #1: Explaining the Injection Molding Process

How to Develop a Product - The 7 Stages of the Product Development Process

Xometry Announces Distribution Partnership with Mitsubishi Materials, U.S.A.

On-demand Webinar: Everything You Need to Know about Vapor Smoothing 3D Prints

On-Demand Webinar: Bring Your Ideas to Life with Custom Manufacturing on Demand

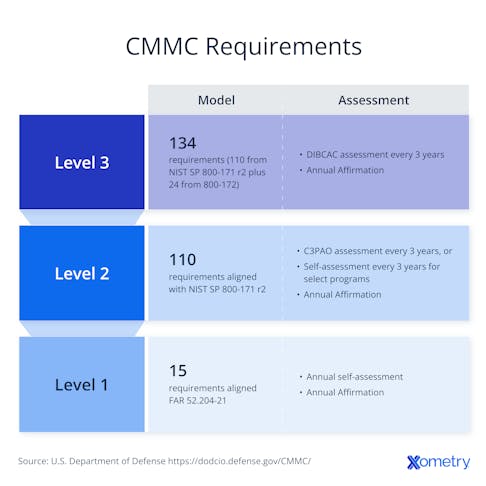

[Webinar Recording] Navigating CMMC Level 2: Compliance & Funding Support for Manufacturers

[Download] 2025 Career Advancement in Manufacturing Report

Xometry’s Ultimate Guide to Direct Part Marking: Laser Marking, Laser Engraving, and More

Small Manufacturing Index, Q1 2018, shows high business confidence and an increase in hiring

[Webinar Recording] From Fusion to Factory: How Xometry Molded Autodesk University’s Macro Keypad

Xometry at IMTS: Commercial Supply Chain Solutions, Laser Tube Cutting Quotes, and More

On-Demand Webinar: How to Ensure Your Supply Chain Can Withstand Disruption (Full Transcript)

[Webinar Recording] Plastic 3D Printing vs. Injection Molding: Making the Best Choice

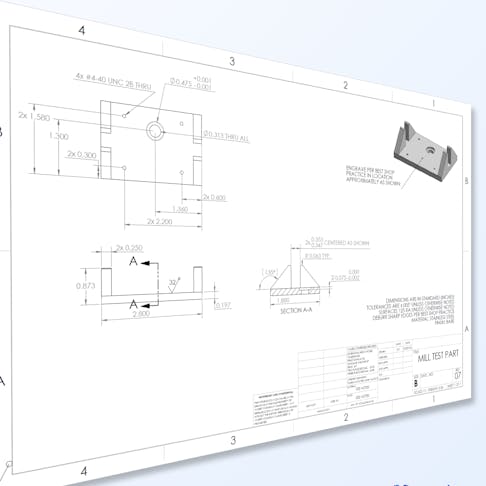

Webinar Recording - Trimming Costs, Keeping Quality: Smart Design Tips for CNC Machining

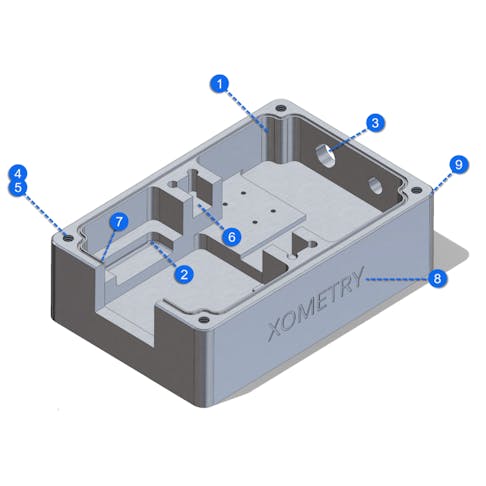

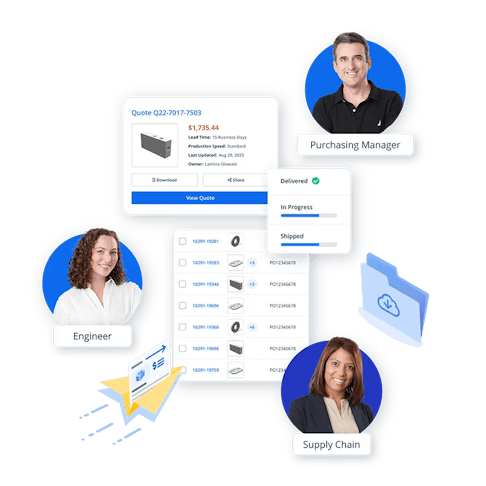

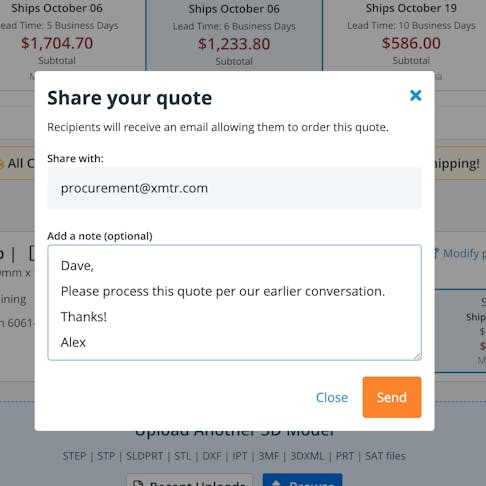

[Webinar Recording] 7 Pro Tips for Mastering Xometry’s Instant Quoting Engine®

[Download] 2024 Career Advancement in Manufacturing Report

Podcast Roundup: Vol. 1, July 2019 | 3Dprint.com, Unprofessional Engineering, MacroFab

Webinar: From Sketch to SKU: Developing XiP, the World’s First Ultrafast Desktop 3D Printer

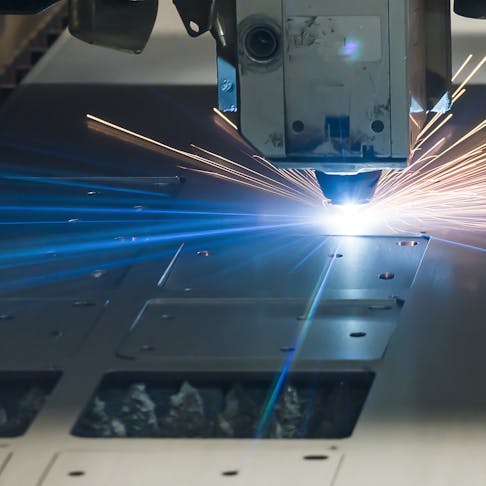

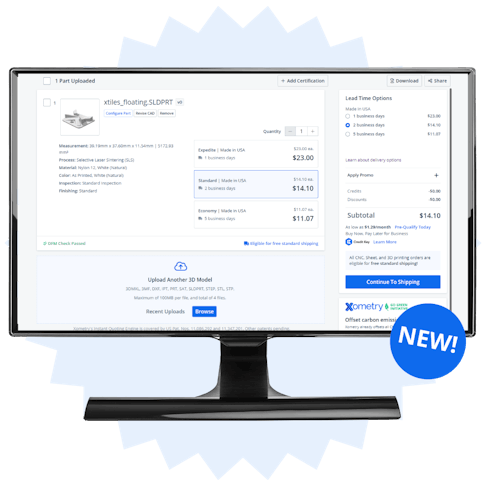

Product Update: Instant Quoting for Laser and WaterJet Sheet Cutting Services

On-Demand Webinar: Master On-Demand Manufacturing with Xometry Greg (April 2020)

Xometry Acquires Shift, Europe’s Largest On-Demand Manufacturing Marketplace

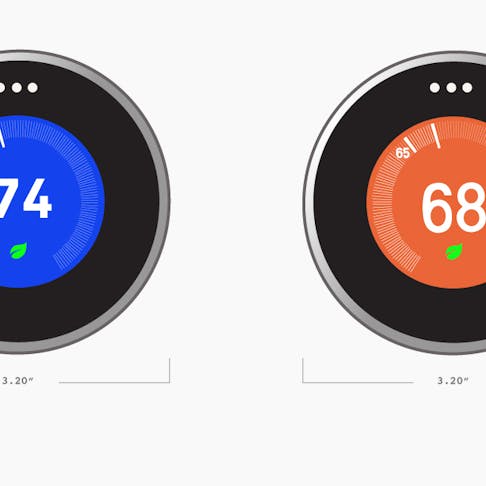

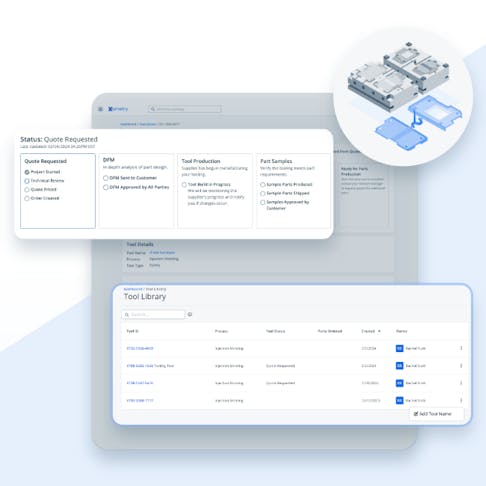

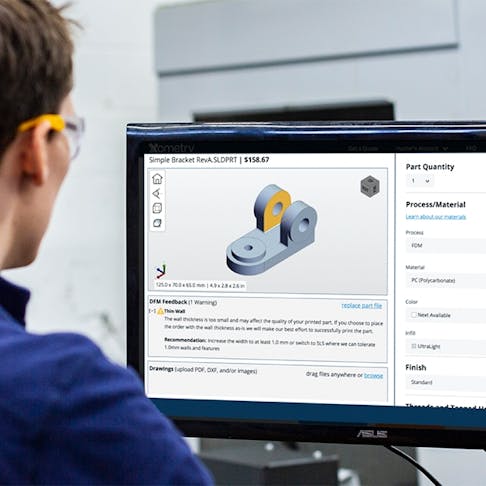

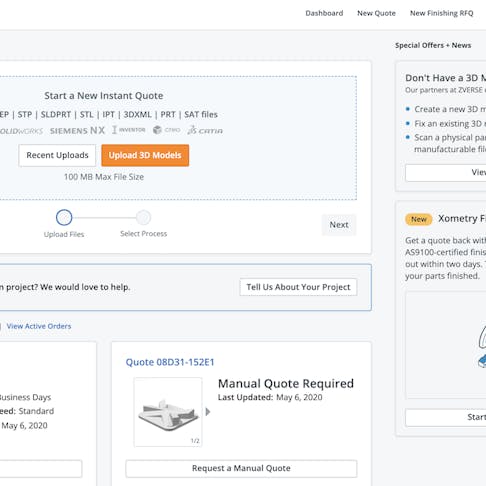

Product Update: Your Personalized Dashboard in the Xometry Instant Quoting Engine℠